A throatless shear is a cutting tool used to make complex straight and curved cuts in sheet metal the throatless shear takes its name from the fact that the metal can be freely moved around the cutting blade it does not have a throat down which metal must be fed allowing great flexibility in shapes that can be cut.

Half shear sheet metal.

I would like to create a half shear.

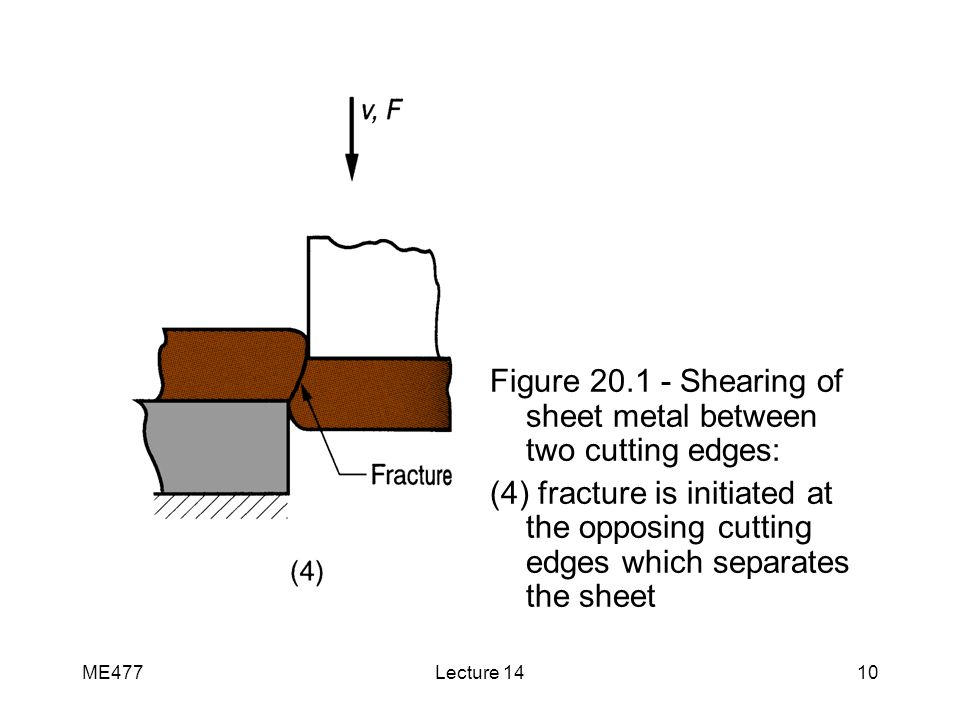

The shearing process is performed on a shear machine often called a squaring shear or power shear that can be operated manually by hand or foot or by hydraulic pneumatic or electric power.

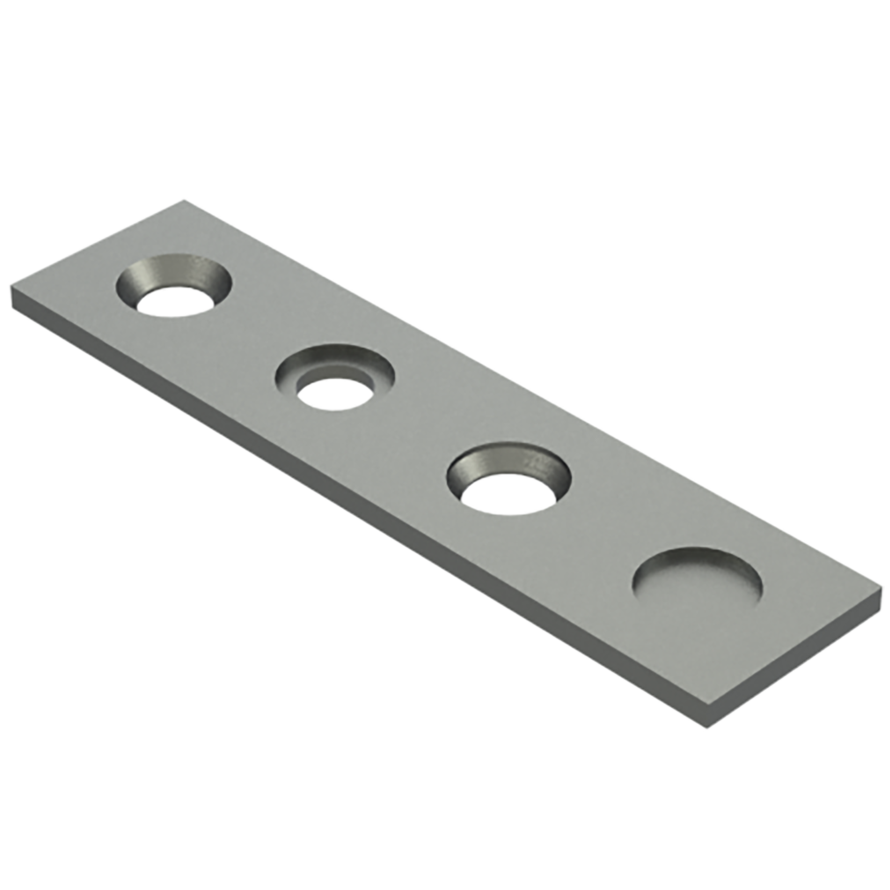

A half shear button is a common sheet metal practice used for accurately locating parts prior to spot welding.

Round half shears make excellent locators for angular shearing and rooftop half shears give you greater height protrusion from the metal which assists in picking up the locator on the sheet.

The range of cordless electric metal shears is currently quite small and the prices high.

If you want to cut metal thicker than 18 gauge you ll need a heavy duty metal shear.

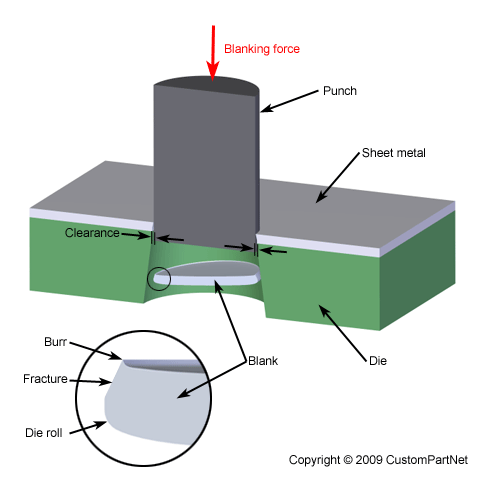

I created a punch punch it does not do what i want it to do.

Geometrically half shears create a pocket on one side and island on the other side of the sheet.

For those of you not familiar with this term i basically want to punch a hole thru metal but only a certain depth not all the way thru.

While you ll find a few at lower price points most are 250 or more.

How do sheet metal shops recognize the feature in your files to indicate what punch to use to create the feature during punch.

Help is much appreciated.

Hi does anyone use half shears for precise locating two pieces of sheet metal to be joined.

The plastic deformation of a piece of sheet metal by tensile loads into a three dimensional shape often without significant changes in sheet thickness or surface characteristics.

Material is 2 4mm thick half shear diameter is 1 5mm and 1 7mm tall.

Half shears are features that can be of any shape that are sheared partially in a sheet.

The half shear from wilson tool is an easy to use tool that allows you to put in shear buttons and spot welding locators to the accuracy of your punch press.

It basically punches a hole at half depth on the front surface while creating a plug of same diameter at half depth out from the backside surface.

How do you create them.

Hot roll 01 uncoated heavy gauge fully processed in strip steel never cold reduced at tandem mill.